WHAT IS LOCK PRE-LOAD?

When talking about preload it is important to understand what preload is and how it impacts a locks ability to function properly.

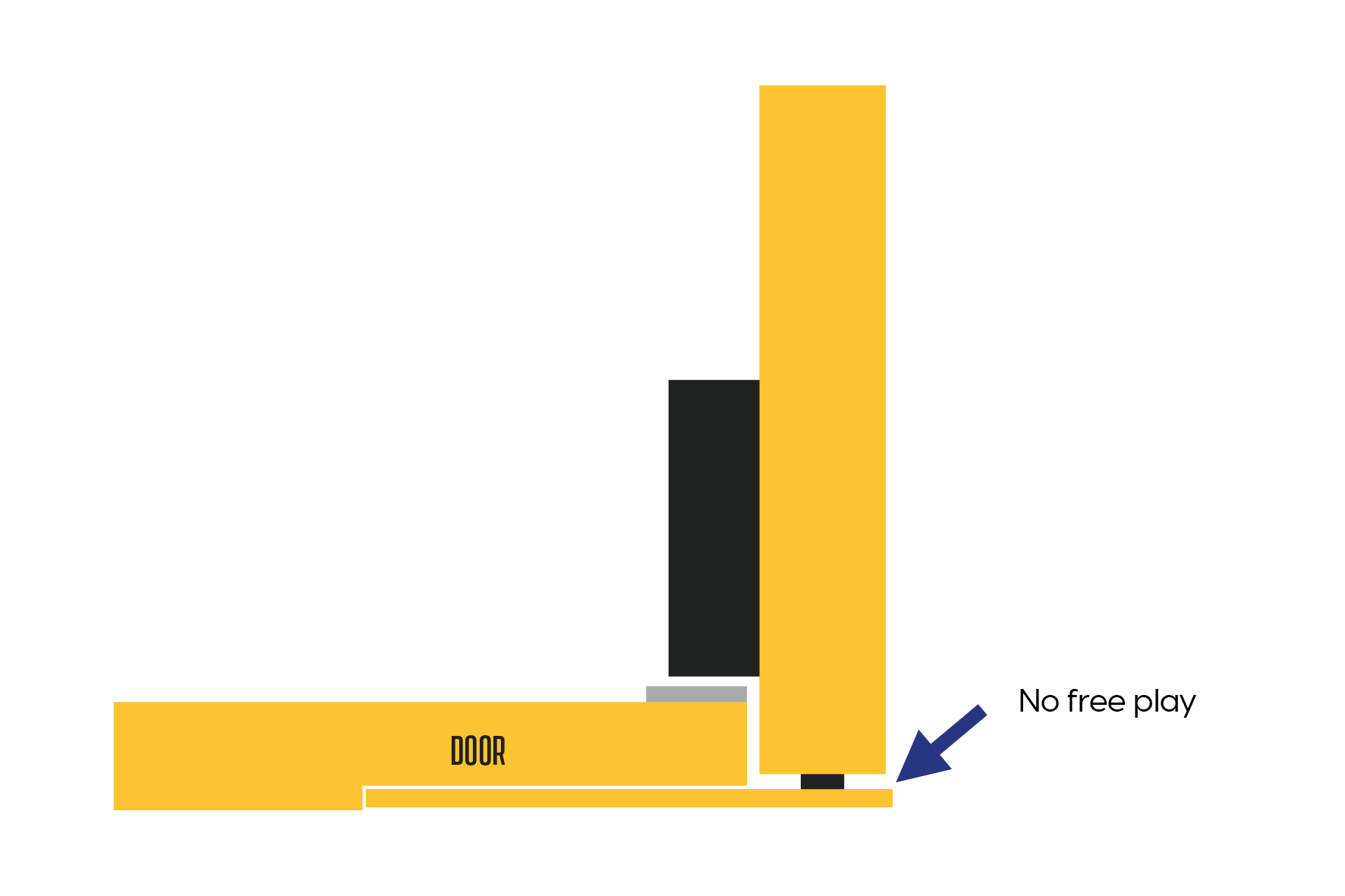

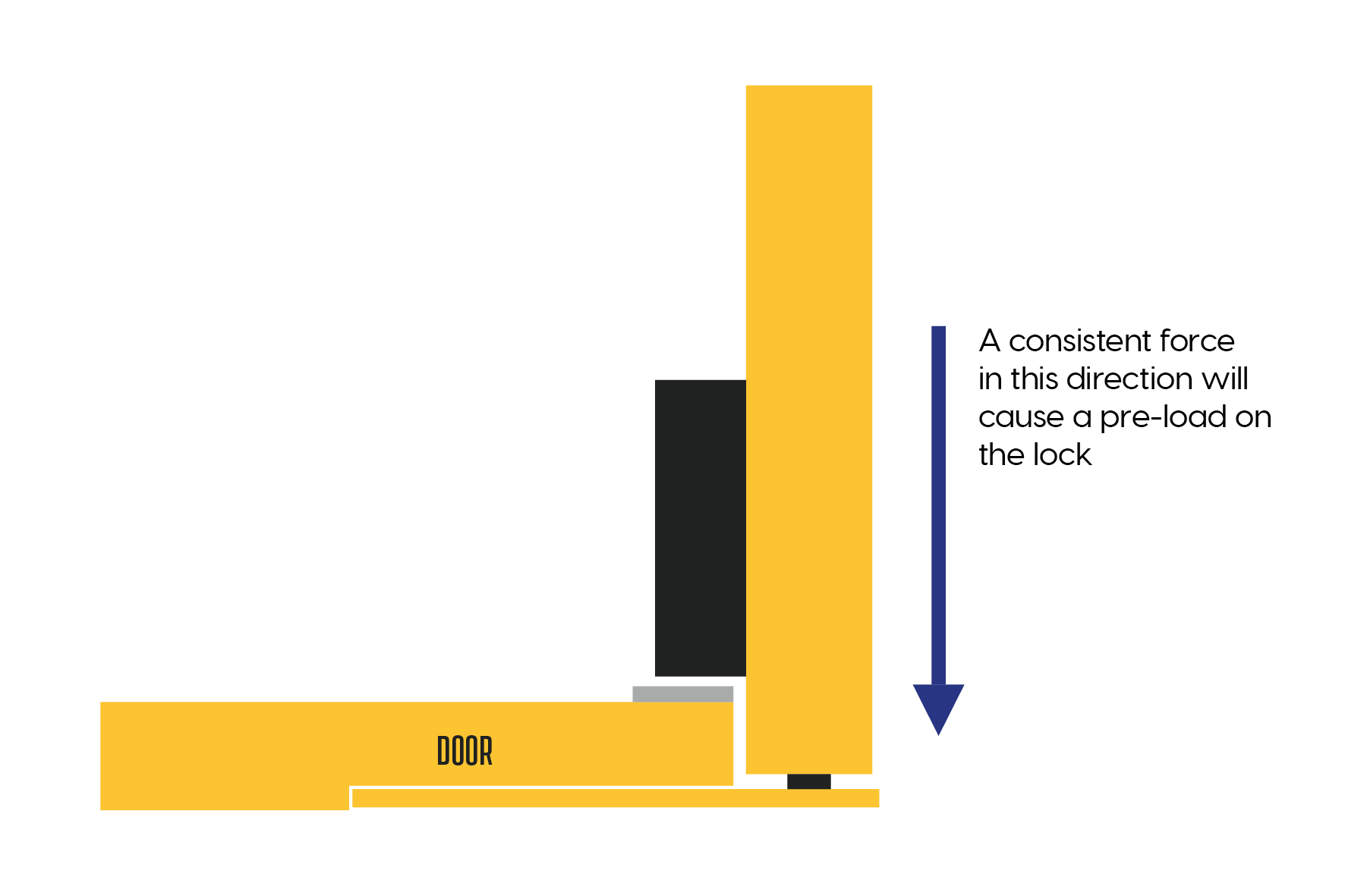

In a locking mechanism, pre-load refers to the force exerted on the lock in an attempt to open it before it has been released. Excessive pre-load can prevent a lock from operating correctly, making it difficult to disengage.

When a lock is installed, it is designed to withstand a certain amount of force, however, if a force is applied to the lock from the side in a consistent manner, this can create pre-load, which can cause damage to the lock. If this happens frequently enough it can affect the locks functionality, which ultimately impacts operation and security.

Camlock Systems' robust locking solutions use powerful motors to overcome these forces, ensuring reliable operation even under high pre-load conditions. For example, if a door is being pushed or sprung open while the lock is engaged, the added force can make unlocking difficult. Our locks are designed to handle such challenges, maintaining both security and ease of use.

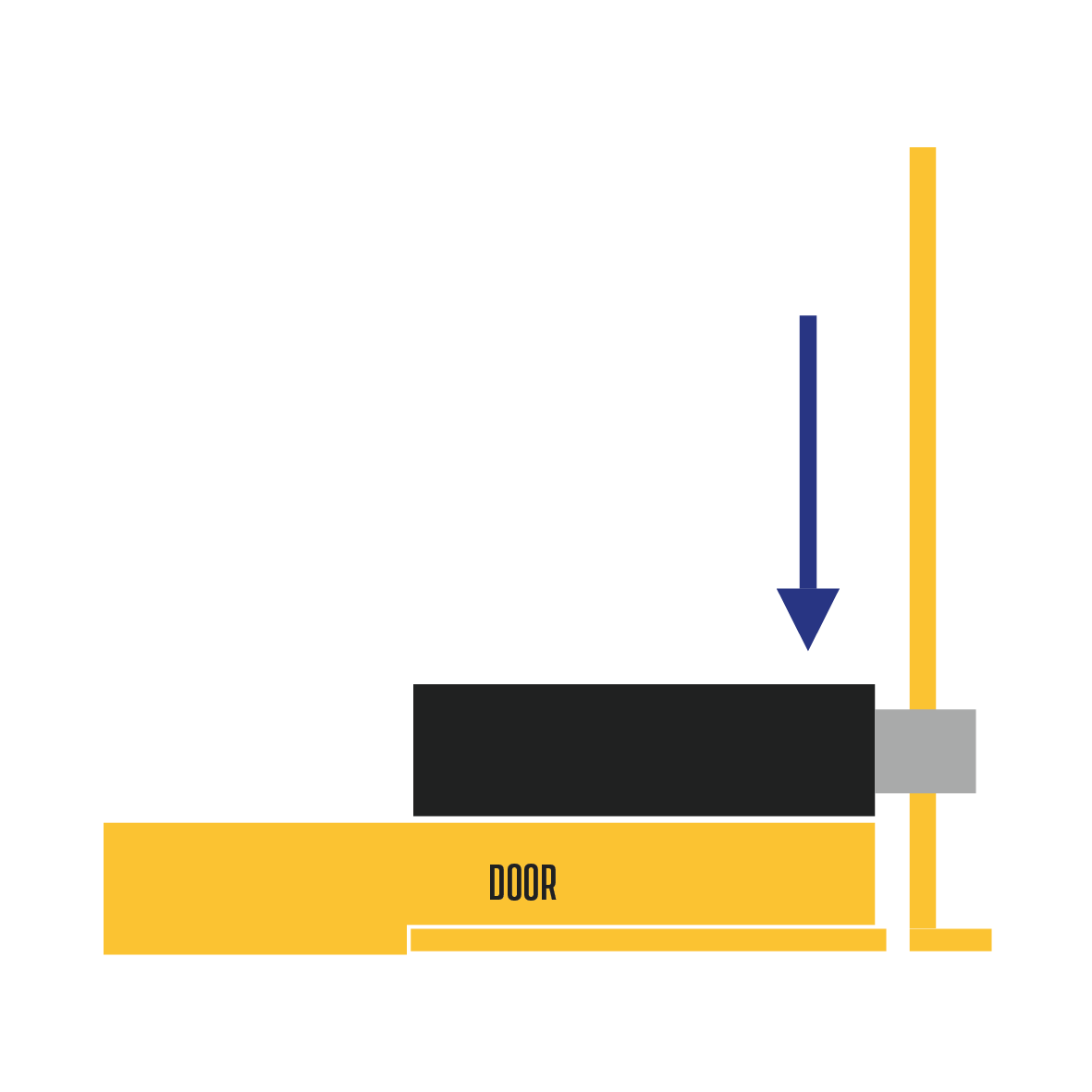

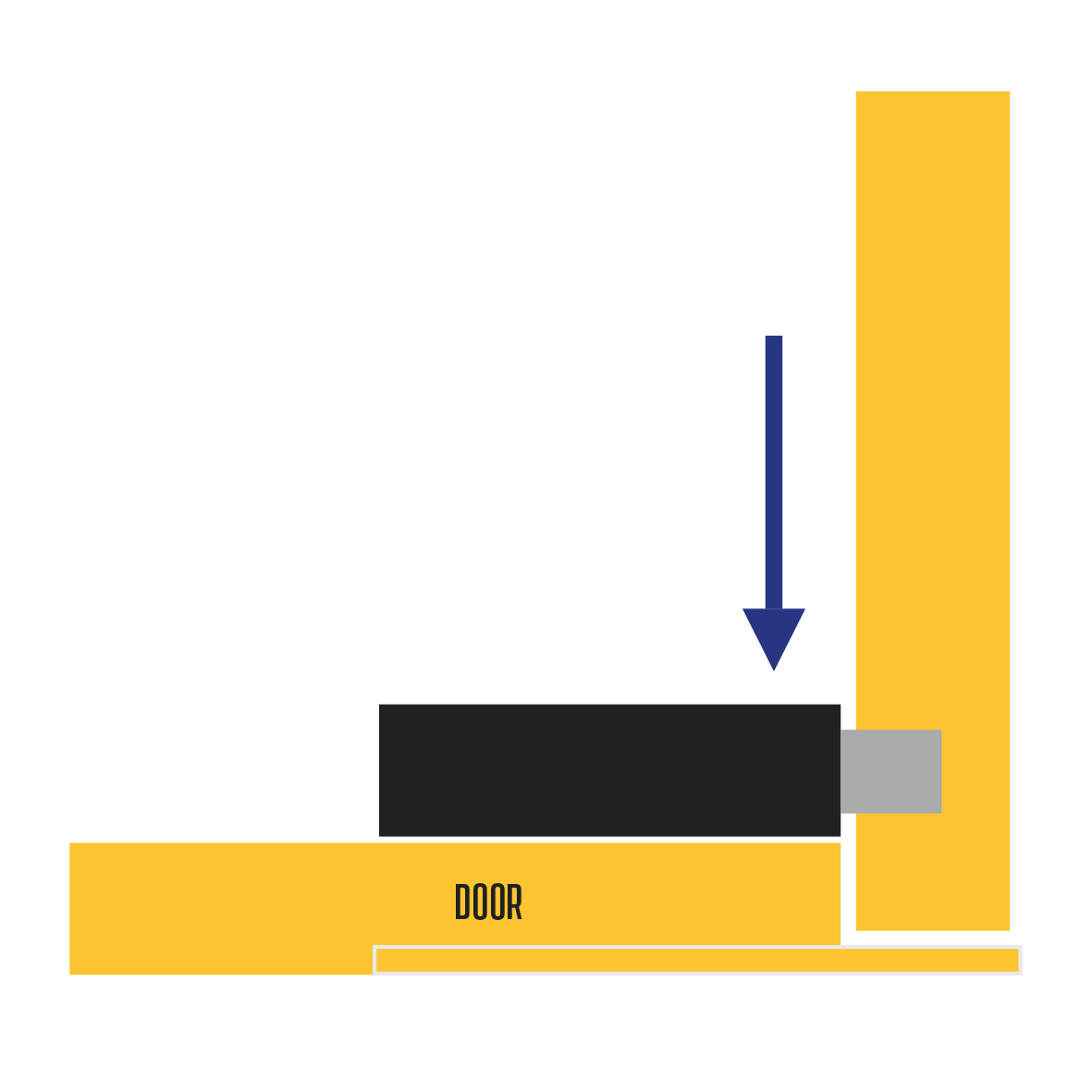

HOW PRE-LOAD OCCURS

When pre-load is applied to an electric lock the force required to open it can vary with different factors, such as a misaligned door or frame, an improperly installed electric strike plate, or, it may come from a designed in factor such as a rubber seal. In some cases, there is not the means to relieve pre-load, for example, it may not be possible to change a rubber seal. A rubber seal on a door will act differently if the temperature is -5 degrees compared to +20 degrees, therefore a lock needs to not only withstand the temperature itself but the contraction and expansion of a rubber seal caused by temperature fluctuation, which may cause pre-load as a result.

Surface structure can also impact pre-load. For example, if a locker is placed on tarmac without a durable surface or proper foundation, which is possible in some public areas, there is a possibility of the unit subsiding on hot days when the tarmac softens. This subsidence could cause the unit to twist and doors to misalign. Misalignment can also occur as the unit ages, through repeated use, or continued slamming of the door which may cause it to become too tight or too loose. In these cases, only a very slight shift is required to have a major impact on pre-load and locking function.

Tampering and attempted forced entry can impact pre-load. If attempts to pry open a door with an electronic lock, the force applied can bend or break parts of the lock or surrounding components causing side load pressure.

Understanding the application, constraints, and environmental factors before installing a lock is an important step for ensuring a latch will function optimally in situations where pre-load may be an issue.

THE EFFECTS OF PRE-LOAD ON AN ELECTRONIC LATCH

When pre-load is applied to a lock it can reduce functionality of the locking system which can lead to issues with the door operation. Electronic locks, like any mechanical or electronic device, have certain tolerances and limitations and pre-load pressure can potentially affect them in several ways, depending on the design and build quality of the lock, such as:

Jamming or Sticking: Excessive sideload pressure can cause components within the lock to jam or stick. This may prevent the lock from functioning correctly, making it difficult or impossible to unlock.

Component Damage: Electronic smart locks contain sensitive electronic components and excessive pressure, or force applied to the lock can damage both the electronic and mechanical components, leading to a malfunction or complete failure of the locking mechanism.

Misalignment: Pre-load pressure can cause misalignment between the lock and the strike, preventing it from engaging or disengaging correctly. In some cases, this may lead to situations where the lock cannot be controlled electronically.

These have wider implications within the application, for example, If the electric strike can’t engage, an operator may not be able to close a vending machine door after refilling, or a customer may not be able to receive their parcels from a locker if pre-load stops the lock from opening. This improper lock operation will affect visibility into the lock door and latch monitoring functionality, and data reports where access control systems are implemented, will have inaccurate information.

Depending on the application, a lock can be set to remain closed (fail locked / fail secure) or, remain open (fail open / fail safe) in the event of a power outage. If pre-load is an issue the lock may not be able to perform this operation, therefore, a vending machine, for example, which is set to be fail locked in the event of a malfunction, may be left with the door open and vulnerable to theft. This can also be applied to applications where a door is required to be fail open, thereby leaving doors locked. This can be problematic in applications where locks are required to be fail open, in the event of an emergency.

Pre-load can have a serious impact of the longevity of a lock. If the locking mechanism becomes damaged as a result of pre-load, the number of cycles it is able to perform can be dramatically reduced, leading to a replacement lock being required to ensure correct operation.

When locks are subject to continuous pre-load, the likelihood of breakage increases and if pre-load is not resolved, the same situation will occur repeatedly. This results in down time of the system and ultimately lost revenue both through the unit being out of action but additionally through the added cost of replacement locks. Even if excessive force doesn't immediately damage the lock, it can accelerate wear and tear on its components, reducing its lifespan and making it more prone to future failures.

HOW TO PREVENT PRE-LOAD

To prevent pre-load from causing damage to an electric lock, it is important to be aware of all the impacting factors to ensure their proper operation and longevity. Pressure and preload issues can cause malfunctions and, in some cases, damage to the lock mechanism or electronics. Preload can be reduced by:

Proper Installation

Regular Maintenance

Proper Sizing and Alignment

Avoid Over-Tightening

Anti-Tampering Measures

Use Quality Components

Proper Installation: Ensuring the lock is installed correctly. Poor installation can lead to preload issues. If a lock is retrofitted, it is important to have a properly designed mounting plate to ensure that the lock sits perfectly.

Regular Maintenance: Regularly inspecting the lock and surrounding components to check for signs of wear, misalignment, or damage, and ensuring any issues are addressed promptly, can prevent them from worsening. Routine maintenance on the lock, including cleaning and lubrication, can prevent the accumulation of dirt and debris that could create pressure on the locking mechanism.

Proper Sizing and Alignment: Ensuring that the lock, strike plate, and any related hardware are properly sized and aligned will reduce unnecessary pressure on the locking mechanism.

Avoid Over-Tightening: When installing the lock or related hardware, avoid over-tightening screws and bolts which can cause pressure on the lock.

Anti-Tampering Measures: Implementing security measures to deter tampering or attempts to force the lock may deter actions which can create pressure on the lock. This may include the use of, access control systems, and proper door reinforcement.

Use Quality Components: Choosing high-quality electronic locks with durable and reliable components. Cheap or poorly manufactured locks are more likely to develop pressure and preload issues.

Overall, pre-load is a vital consideration when it comes to electric locks, as it can impact functionality and therefore effectiveness and longevity. Not every lock is built to withstand pre-load and it’s an important consideration. By taking steps to prevent and address pre-load, it is possible to ensure that an electronic lock will function properly and providing a reliable, durable solution for many years.